-

tel: +86-514-80362362

-

email: sales@yadon.com.cn

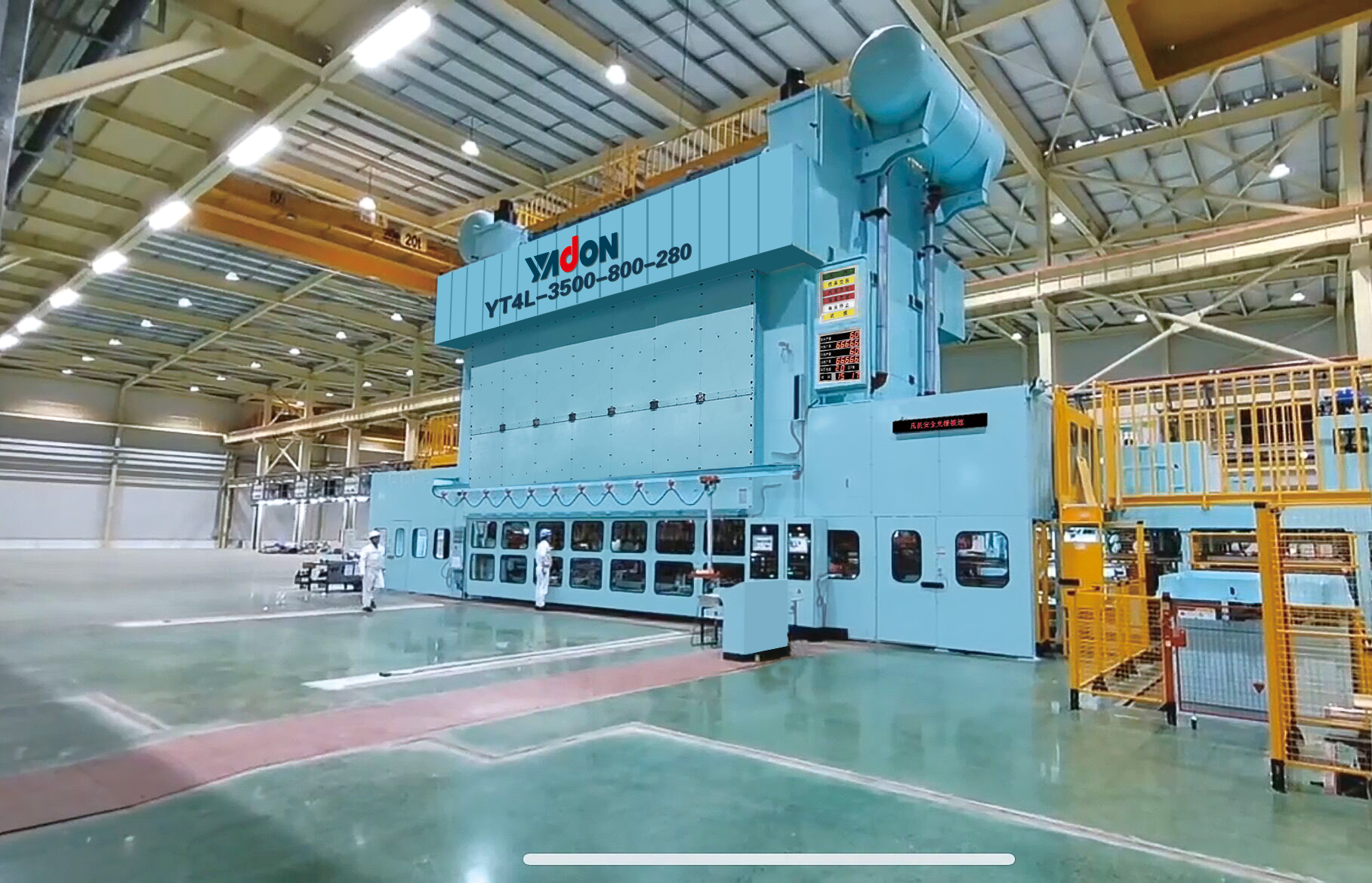

The Industry's First 3500T Multi-Link Transfer Press Line Put into Operation

The Industry's First 3500T Multi-Link Transfer Press Line Put into Operation

Mar 18, 2025

In February 2025, Yangzhou Metalforming Machine Tool Co., Ltd. (Yadon) delivered the industry's first 3500T multi-link transfer mechanical press line to a Japanese Tier 1 automotive manufacturer. This line is designed for high-speed precision stamping of large, high-strength sheet metal components for new energy vehicles.

Customer Evaluation:

The customer highly praised the production line, stating that the ultra-large transfer press line achieves over 20 strokes per minute with stable efficiency. Compared to traditional tandem press lines, it requires less floor space, lower operation and maintenance costs, and higher productivity. Integrated with a quick die-change system, it significantly enhances efficiency in batch production of multi-variety stamped parts, further boosting the customer's competitiveness.

To date, this Japanese Tier 1 customer has adopted Yadon press lines ranging from 800T to 3500T. Yadon presses have met stringent requirements for speed, performance, and operational rate, matching the standards of global top-tier press manufacturers and earning long-term trust. Thanks to Yadon’s superior technology and product quality, the 3500T multi-station press has already received multiple domestic and international orders.

Technological Integration and Leadership:

Yadon’s transfer presses incorporate Schuler’s globally leading technologies, featuring a deeply optimized multi-link drive structure and covering dual-point and four-point configurations. Since delivering its first 2500T ultra-large multi-station press in early 2018, Yadon has cumulatively supplied over 30 units, all operating stably. With outstanding technology, stability, productivity, and sales volume, Yadon has solidified its position as a global leader in multi-station press manufacturing.

Manufacturing Excellence:

With nearly 70 years of experience in mechanical press production, Yadon possesses advanced capabilities in welding and machining critical components such as frames, large gears, multi-link mechanisms, and drive shafts. From welding, heat treatment, precision machining, inspection, to assembly, every process strictly adheres to Schuler’s technical and process standards. The integration of lean manufacturing and MES intelligent systems ensures compliance with the industry’s most rigorous production requirements.

YT4L Large CNC Closed Four-Point Multi-Link Transfer Press Line:

As part of China’s strategic emerging industries in high-end intelligent manufacturing equipment, this line centers on a large multi-link multi-station press. It integrates advanced functions such as sheet separation, automatic material handling, double-sheet detection, servo feeding, centering and positioning, triaxial robotic multi-station transfer, inspection platforms, scrap disposal, and automatic die-changing, forming a high-efficiency, precision, intelligent stamping line for automotive structural components.

Key Advantages:

High Efficiency: Full-load production rate of 8 ~ 30 strokes per minute.

High Precision: Repeated positioning accuracy of ±0.05mm for the worktable; ±0.1mm for servo step feeding, ensuring precision stamping of automotive parts.

Flexibility: Enables fully automated stamping of multiple types and specifications of high-strength steel automotive components.

Intelligence: Supports smart control, remote diagnostics, online fault detection, maintenance guidance, and production data management.

Breakthrough Technologies:

Yadon heavy-duty transfer presses have overcome core challenges in structural machining, multi-link drive design, intelligent control for high-strength steel stamping, dynamic performance measurement, and anti-eccentric-load technology, ensuring stability, reliability, efficiency, and intelligence. The technology has yielded 2 invention patents, 6 utility model patents, and 3 new patent applications.

Customer Evaluation:

The customer highly praised the production line, stating that the ultra-large transfer press line achieves over 20 strokes per minute with stable efficiency. Compared to traditional tandem press lines, it requires less floor space, lower operation and maintenance costs, and higher productivity. Integrated with a quick die-change system, it significantly enhances efficiency in batch production of multi-variety stamped parts, further boosting the customer's competitiveness.

To date, this Japanese Tier 1 customer has adopted Yadon press lines ranging from 800T to 3500T. Yadon presses have met stringent requirements for speed, performance, and operational rate, matching the standards of global top-tier press manufacturers and earning long-term trust. Thanks to Yadon’s superior technology and product quality, the 3500T multi-station press has already received multiple domestic and international orders.

Technological Integration and Leadership:

Yadon’s transfer presses incorporate Schuler’s globally leading technologies, featuring a deeply optimized multi-link drive structure and covering dual-point and four-point configurations. Since delivering its first 2500T ultra-large multi-station press in early 2018, Yadon has cumulatively supplied over 30 units, all operating stably. With outstanding technology, stability, productivity, and sales volume, Yadon has solidified its position as a global leader in multi-station press manufacturing.

Manufacturing Excellence:

With nearly 70 years of experience in mechanical press production, Yadon possesses advanced capabilities in welding and machining critical components such as frames, large gears, multi-link mechanisms, and drive shafts. From welding, heat treatment, precision machining, inspection, to assembly, every process strictly adheres to Schuler’s technical and process standards. The integration of lean manufacturing and MES intelligent systems ensures compliance with the industry’s most rigorous production requirements.

YT4L Large CNC Closed Four-Point Multi-Link Transfer Press Line:

As part of China’s strategic emerging industries in high-end intelligent manufacturing equipment, this line centers on a large multi-link multi-station press. It integrates advanced functions such as sheet separation, automatic material handling, double-sheet detection, servo feeding, centering and positioning, triaxial robotic multi-station transfer, inspection platforms, scrap disposal, and automatic die-changing, forming a high-efficiency, precision, intelligent stamping line for automotive structural components.

Key Advantages:

High Efficiency: Full-load production rate of 8 ~ 30 strokes per minute.

High Precision: Repeated positioning accuracy of ±0.05mm for the worktable; ±0.1mm for servo step feeding, ensuring precision stamping of automotive parts.

Flexibility: Enables fully automated stamping of multiple types and specifications of high-strength steel automotive components.

Intelligence: Supports smart control, remote diagnostics, online fault detection, maintenance guidance, and production data management.

Breakthrough Technologies:

Yadon heavy-duty transfer presses have overcome core challenges in structural machining, multi-link drive design, intelligent control for high-strength steel stamping, dynamic performance measurement, and anti-eccentric-load technology, ensuring stability, reliability, efficiency, and intelligence. The technology has yielded 2 invention patents, 6 utility model patents, and 3 new patent applications.

Arabic

Arabic

Russian

Russian

Portuguese

Portuguese

Japanese

Japanese

SALUD

SALUD